Water is one of the most important utilities used in the textile industry, especially in the wet processing industry. Without water, no one can imagine scouring, bleaching, dyeing, finishing, etc. There are mainly four main sources of water, such as rainwater, surface water, subsoil water, and deep well water. Mainly in Bangladesh deep well water is available most of the companies use deep well water. The boiler’s water, scouring, bleaching, dyeing, and finishing, must be soft and clean.

A water treatment plant is necessary for every wet processing industry. In wet textile processing, water is required for dyeing, painting, fishing, and garment washing. We know water has two types, hard water and soft water. the water which is collected from up of the soil or under the soil. It may contain different chemical substances which makes the water hard. The hard water is not suitable for wet processing. For this reason, it is required to purify the hard water. after purification by the water treatment plant, water becomes ready for the next wet process.

Water treatment plant

The water available from different sources cannot be used directly in boilers. The objective of the water treatment plant is to produce the boiler feed water so that there shall be:

1. No scale formation

2. No corrosion

3. No fouling

The treated water is called ‘De-mineralized Water’ and the plant where it is treated is called a Water Treatment Plant.

There are two types of water prepared in a water treatment plant:

1. Clarified water for washing purposes.

2. Soft water for dyeing purposes.

Standard for Textile Dye House Water Supply:

| Parameter | Permissible concentration |

|---|---|

| Color | Colorless |

| Smell | No Bad Smell |

| Water Hardness | <5 ppm |

| pH value | should be 7-8 (Neutral) |

| Dissolve solid | < 1 ppm |

| Inorganic salt | < 500 ppm |

| Iron (Fe) | < 0.1 ppm |

| Manganese (Mn) | < 0.01 ppm |

| Copper (Cu) | <0.005 ppm |

| Nitrate (NO3) | < 50 ppm |

| Nitrate (NO2) | < 5 ppm |

| Solid content | < 50mg/L |

Quality Requirements of Boiler Water:

The boiler needs a very special quality of water.

Table 2: Acceptable limits of property of water in the boiler

| Properties | Acceptance limits |

|---|---|

| Appearance | Clean with residue |

| Residue as hardness | 0.050 dH |

| Temporary CO2 | 0 mg/L |

| Temporary Fe | < 0.02 mg/L |

| pH | >9 |

| Conductivity | < 2500μs/cm |

| Feed water temp. | 70oC to 90oC |

The supply water contains various soluble effluents like dissolved solids, metal compounds, and other impurities that can lead to any fabric fault during dyeing the knitted fabrics. That’s why, it’s essential to set up an industrial water treatment plant (WTP) to maintain the water quality.

The flow chart of the water treatment plant is as follows:

Process Sequence of Water Treatment Plant:

Process Sequence of Water Treatment Plan

Deep pump water supply

Raw water Tank

WTP Pump

Air Receiver Tank

Vessel

Iron Remover Tank

Multi-grade Filter

Activated Carbon Filter

Softener Tank or Filter

Brain tank

Soft water reserve Tank

Booster Pump

Dye House

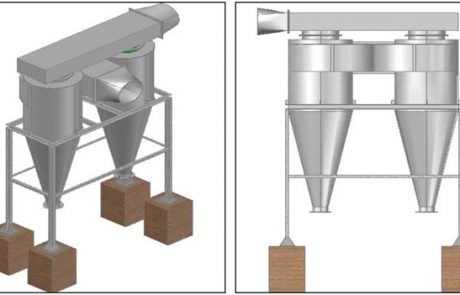

Conventional Water Treatment Plant:

The water treatment process may vary slightly at different locations, depending on the technology of the plant and the water it needs to process, but the basic principles are largely the same. This section describes standard water treatment processes.

Below mentioned are the steps involved in the Water Treatment Plant Process.

1. Coagulation / Flocculation

During coagulation, liquid aluminum sulfate (alum) and polymer are added to untreated (raw) water. When mixed with the water, this causes the tiny particles of dirt in the water to stick together or coagulate. Next, groups of dirt particles stick together to form larger, heavier particles called flocs which are easier to remove by settling or filtration.

2. Sedimentation

As the water and the floc particles progress through the treatment process, they move into sedimentation basins where the water moves slowly, causing the heavy floc particles to settle to the bottom. Floc which collects on the bottom of the basin is called sludge and is piped to drying lagoons. In Direct Filtration, the sedimentation step is not included, and the floc is removed by filtration only.

3. Filtration

Water flows through a filter designed to remove particles in the water. The filters are made of layers of sand and gravel, and in some cases, crushed anthracite. Filtration collects the suspended impurities in water and enhances the effectiveness of disinfection. The filters are routinely cleaned by backwashing.

4. Disinfection

Water is disinfected before it enters the distribution system to ensure that any disease-causing bacteria, viruses, and parasites are destroyed. Chlorine is used because it is a very effective disinfectant, and residual concentrations can be maintained to guard against possible biological contamination in the water distribution system.

5. Sludge Drying

Solids collected and settled out of the water by sedimentation and filtration are removed to dry lagoons.

6. Fluoridation

Water fluoridation is the treatment of community water supplies to adjust the concentration of the free fluoride ions to the optimum level sufficient to reduce dental caries. Hunter Water is required to fluoridate water by the NSW Fluoridation of Public Water Supplies Act 1957.

7. pH Correction

Lime is added to the filtered water to adjust the pH and stabilize the naturally soft water to minimize corrosion in the distribution system and within customers’ plumbing.

Chemicals are-Used in WTP:

1. Aluminum Sulphate

2. Polyelectrolyte

3. Sodium Chloride

4. Amount of Chemical Used:

5. Polymer- .1% solution

6. Al2 (SO4)3- 10% solution

7. Lime- 10% solution

Experiments Performed in WTP:

1. Total water hardness test

2. Jar test

3. pH meter test

4. Titration for chlorine content test

Purpose of Water Treatment Plant:

1. To remove the hardness of water and purification of water.

2. To supply water to the dye house as stander quality.

3. To supply water to the boiler as it does not damage the boiler.

Activated Carbon Filter (ACF)

Carbon filtering is a method of filtering that uses a bed of activated carbon to remove contaminants and impurities, using chemical adsorption. … Active charcoal carbon filters are most effective at removing chlorine, particles such as sediment, volatile organic compounds (VOCs), taste, and odor from water.

Multi Grade Filter (MGF)

A multigrade filter is a depth filter that makes use of coarse and fine media mixed in a fixed proportion. This arrangement produces a filter bed with adequate pore dimensions for retaining both large and small suspended particles. This filter performs at a substantially higher specific flow rate than conventional filters.