Iron Removal Plant is the most effective solution in the Industrial Water Purifier Sector in Bangladesh, It is widely used for Industrial solutions as well as home use. Our Industrial Reverse Osmosis Plants and Iron Removal Plant are carefully customized and configured to suit the individual requirement of the output water, which varies from normal drinking water application to specific usage, such as food Processing plants and others. Our design Iron Removal Plant consists of FRP Vessel Manganese Zeolite Zeomangan Birm Media Graded Sand TIRM Media Anthracite Granular Activated Carbon SS Centrifugal Pump and imported Food Graded uPVC Pipe and Fittings.

Our Iron Removal Plant is used for the treatment of groundwater and surface water typically for the reduction of iron, manganese, and ammonium, and aggressively in waterworks, companies, and private households.

Pressure filter plants can also be used for special fields of application such as de-chlorination of water, reuse of process water, filtration of seawater, percolate filtration, and final filtration of industrial or municipal wastewater.

See certification

Our specially designed Iron Removal Plant (IRP) can remove metals and chemical contamination up to 35 PPM. Our IRPs are provided with highly adsorptive filters to trap even the last trace of iron content in water, rendering clean and healthy water. Our used Filter Media, Chemicals, and FRP vessels are cost-effective and long-life usable.

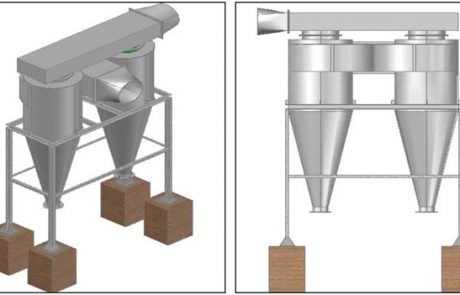

We offer our clients an encompassing range of Iron Removal Plant which is widely used for the removal of excess iron content present in the water. All our plant designs are completely customized so that we can meet the client’s requirements efficiently and effectively. The Iron Removal Plant we offer is manufactured with high-grade raw material. We have a wide range of units like Iron Removal Plant for flats apartments and residential establishments, Industrial Iron Removal, FRP Iron Removal, and MS Iron Removal.

Our specially designed Iron Removal Plant can remove metals and chemical contamination. We design the highest adsorptive filters to trap even the last trace of iron content in your water, rendering clean and healthy water.

Iron Removal Treatment Concept

The different techniques for Iron removal Plants in physical-chemical ways based on water pH, Iron content, hardness, etc are as given below.

Treatment Features

The Iron Removal Scheme of Flow capacity 0.50 to as per required cu.m/hr is designed and proposed by us based on Raw inlet water quality and site conditions to produce Iron-free potable water as per IS and WHO standards. The different components of our IRON REMOVAL SYSTEM are given below.

Iron Removal Treatment Components

IRON REMOVAL PLANT PROCESS:

Media will be used according to the level of iron in raw water and also according to the production capacity

1. Feed pump: In the kind of IRON REMOVAL PLANT feed pump is the first step. In the IRON REMOVAL PLANT feed pump transfers water from the raw tank to the pre-treatment unit. if the raw water tank is empty then the feed pump and total IRON REMOVAL PLANT will be automatically stopped.

2. Non-return bulb: In an IRON REMOVAL PLANT when you stop the machine after passing the water by the feed pump then the non-return bulb will guard the water not coming back.

3. Feed pump pressure switch: In an IRON REMOVAL PLANT if any vessel or filter is blocked, if the pressure is more than 4kg then the feed pump will automatically stop.

4. Water sample bulb: To justify the activity of chemicals or filters in every step of an IRON REMOVAL PLANT, you have to use a water sample bulb to take water.

5. Multi Media filter: Media used-manganese zeolite, Anthracite, Birm, Sand, Gravel ): It removes iron arsenic, rust, sulfur, manganese, Drit turbidity, bad taste, odor, and even chlorine by using iron removal media in IRON REMOVAL PLANT.

6. Sand filter: In an IRON REMOVAL PLANT sand filter reduce d cast and clean water.

7. Activated carbon filter: In an IRON REMOVAL PLANT activated carbon filter absorbs dirt, lead, chlorine, mercury, and bad taste and odor. By removing these particles it will reduce the turbidity and make the water crystal clear.

8. Micron filter: In the IRON REMOVAL PLANT micron filter is also known as the security filter, because it cleans the water again and doesn’t shed any kind of dust before the water goes to the next step.

9. Level switch: when the pure water tank is full in the IRON REMOVAL PLANT in Bangladesh the RO machine will automatically stop.

We also deal with various other water treatment plants like Arsenic Removal Plant, and Fluoride Removal Plant. We are also capable of manufacturing MS vessels for Iron Removal filters as per customers’ requirements.

We design, supply, and install Iron removal systems to achieve iron within permissible levels.

Applications

- Hotels

- Holiday Resorts,

- Accommodation Centers,

- Housing / Residential Complexes,

- Townships,

- Commercial Buildings,

- Hospitals,

- Remote Camp Bases,

- Captive Power, Plants,

- Industries.

- Education Institution/colleges

- Domestic